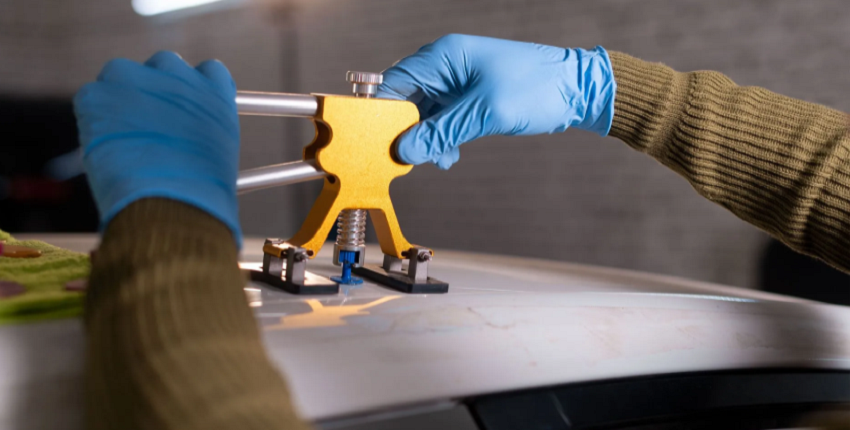

What is Paintless Dent Repair (PDR)?

Paintless Dent Repair (PDR) is an innovative and advanced method for repairing dents and surface damage on vehicles without the need for repainting or filler. It is ideal for fixing minor dents caused by hail, door dings, or small objects. Since it doesn’t involve repainting, PDR helps maintain the original value of the car.

Advantages of PDR:

- Preserves Original Paint: No need for paint matching or repainting.

- Lower Cost: Reduces overall repair costs by eliminating painting steps.

- Faster Repairs: Quicker than traditional repair methods.

- Maintains Vehicle Value: Restores the body without altering the original paint.

- Eco-Friendly: Avoids the use of chemicals and paints that can be pollutants.

PDR Equipment Manufacturers:

- DentFix (USA): Offers professional-grade PDR equipment.

- Anson PDR (USA): Renowned for producing high-quality PDR tools.

- GYS (France): Specializes in advanced multi-purpose repair tools.

- Ultra Dent Tools (USA): Provides durable, high-quality tools for professionals.

- PDR Finesse Tools (USA): Known for precise and specialized PDR equipment.

- A1 Tool (USA): Produces custom-designed, high-quality PDR tools.

Technical Specifications of PDR Tools:

-

PDR Tool Kit:

Includes various levers and rods of different lengths and angles for accessing different areas of the car body.

-

PDR Light Board:

Specialized lighting for precise detection of dents and inspection of repair quality.

-

Glue Pulling Tabs:

Used to fix dents that are inaccessible from the backside of the panel.

-

Knockdown Tools:

Plastic or metal hammers for final adjustments to the surface after dent removal.

-

Heat Gun:

Softens the paint during the repair process, especially in colder weather.

-

Ergonomic Tool Design:

Provides ease of use and reduces fatigue for technicians.